Smart Mine Comprehensive Management Solution: Deep Integration of Intelligent Safety and Production Automation

Category: Industry News

2024-11-19

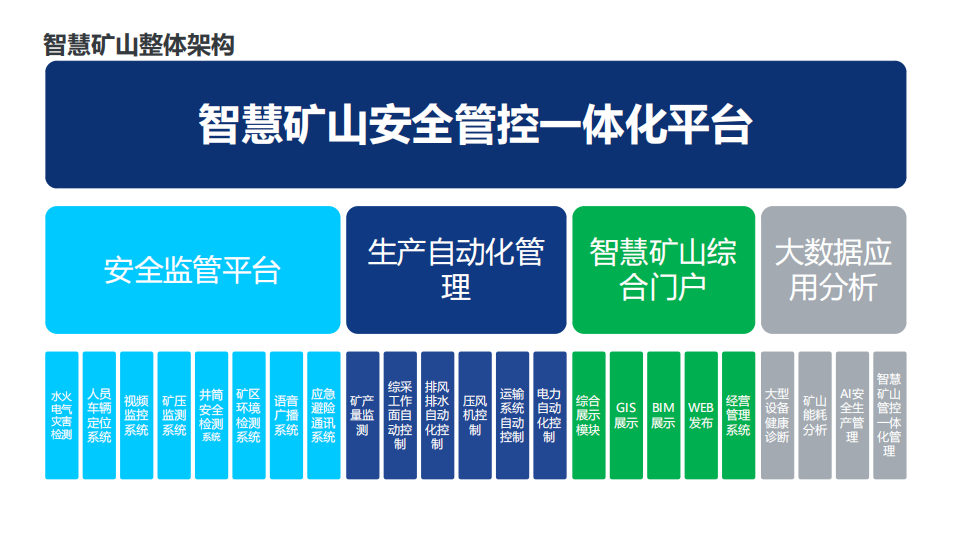

The overall solution for smart mines aims to provide a comprehensive and efficient safety production and automation management system for the mining industry through the deep application of intelligent technology. The plan not only involves digital transformation of various aspects of mining production, but also combines cutting-edge technologies such as the Internet of Things, big data, and AI to achieve comprehensive coverage from safety monitoring to production automation. This solution, combined with current mining trends, provides a technological innovation path for mining enterprises, enabling them to achieve a qualitative leap in production efficiency, resource scheduling, and safety assurance.

1. Industry background and demand analysis: The mining industry has long faced complex operating environments and high-risk production conditions. Traditional management methods have many shortcomings in information sharing, risk control, resource scheduling, and cannot meet the needs of modern mining management. With the development of intelligent technology, mining enterprises urgently need to improve their safety production level, reduce operating costs, and enhance market competitiveness through digital and automated means. The plan closely integrates with the current industry situation and proposes a complete smart mine management system.

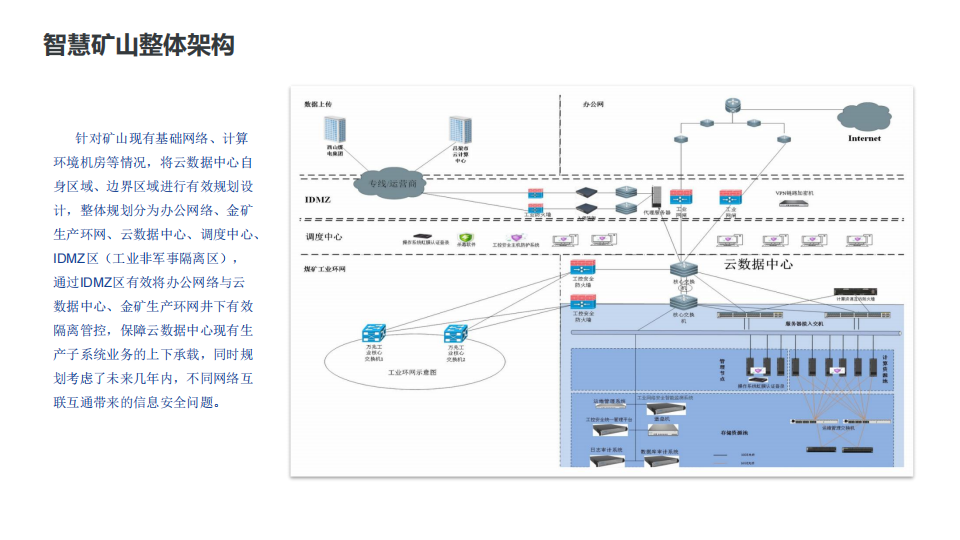

2. The overall architecture scheme of the smart mine adopts a layered overall architecture design, covering the interconnection of cloud data center, production ring network, office network and scheduling center. By introducing industrial non military isolation zones (IDMZ), the isolation and control of office networks and production ring networks have been achieved, ensuring the security of the system. At the same time, in response to the unique geographical environment and complex production processes of mines, the plan provides precise network interconnection planning for different production areas and subsystems, enabling various production activities in mines to be efficiently carried out under the premise of information security.

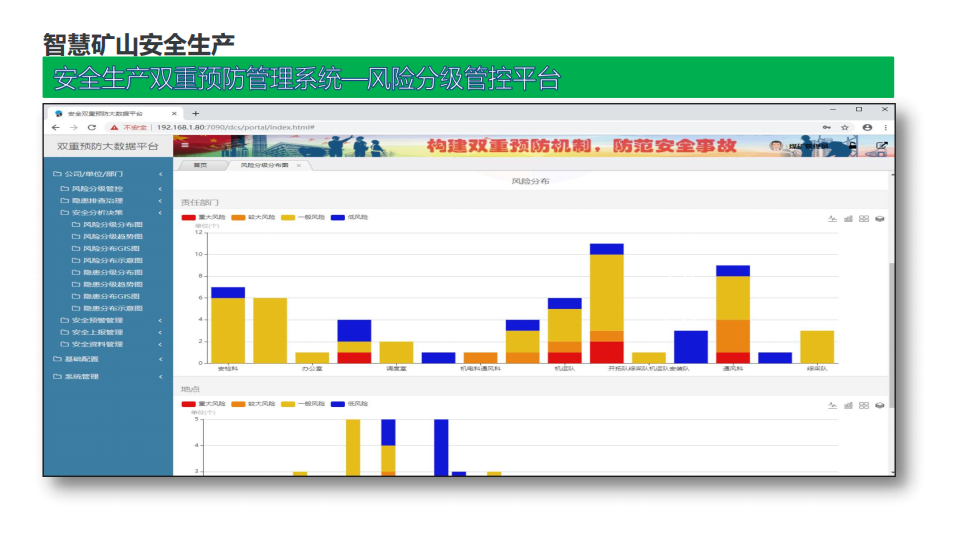

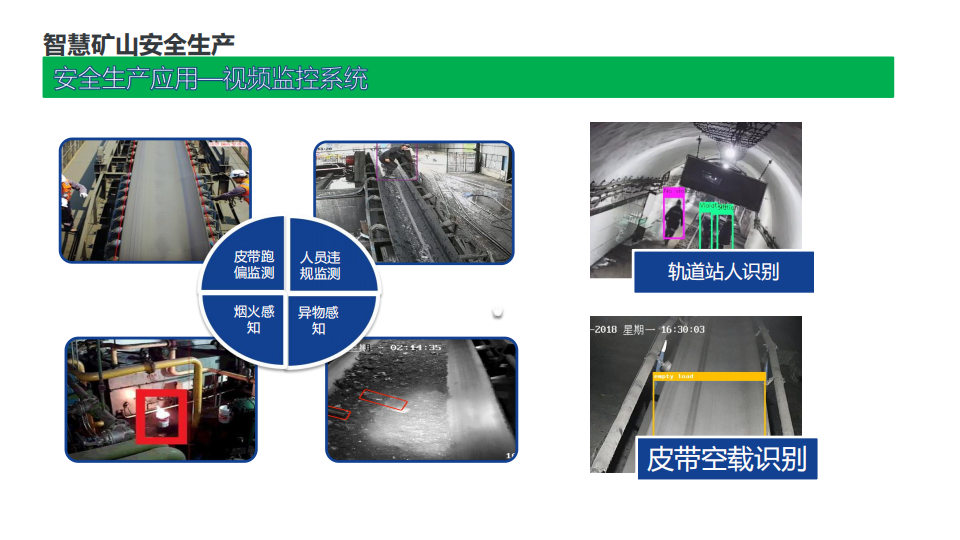

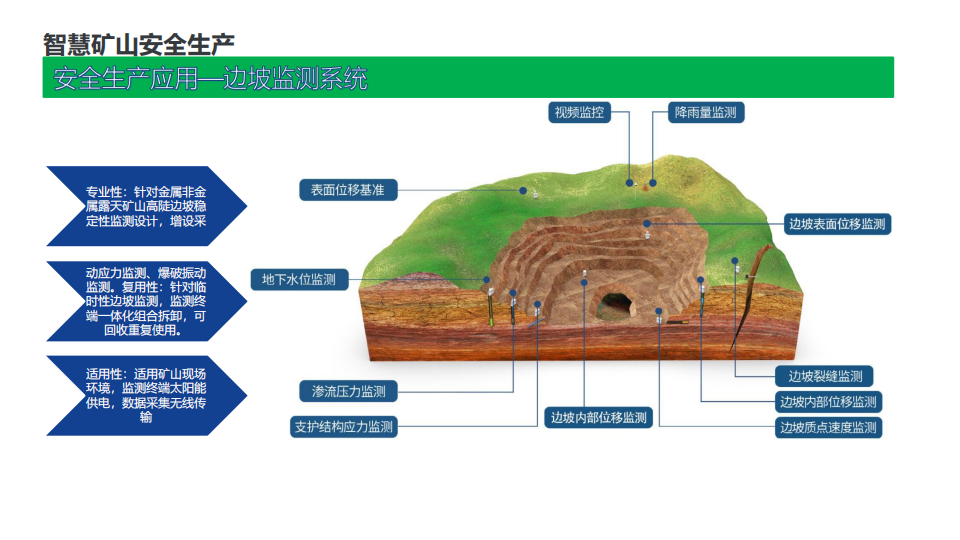

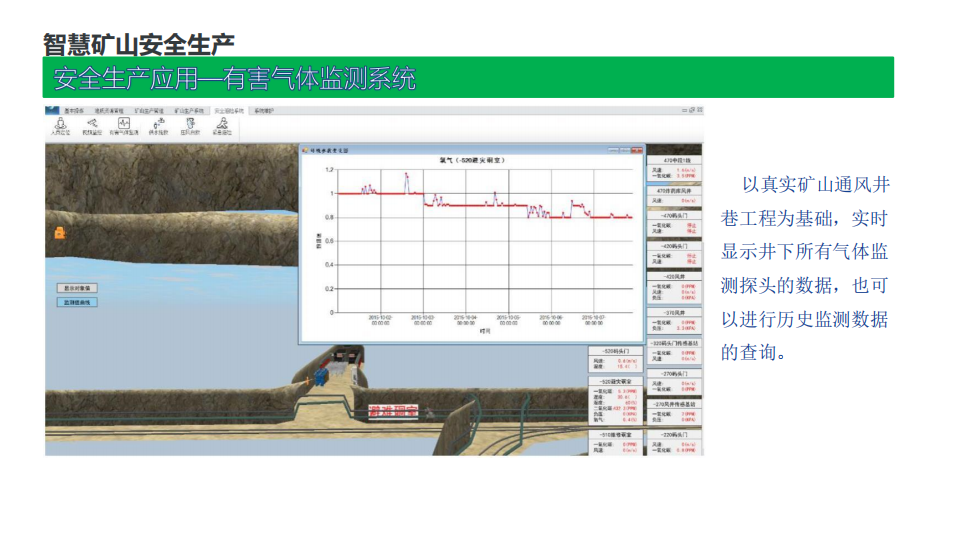

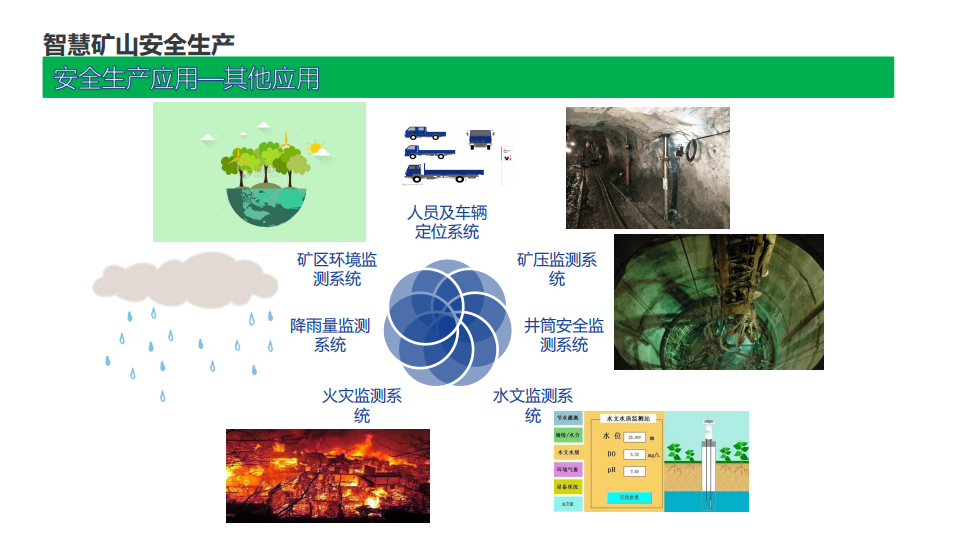

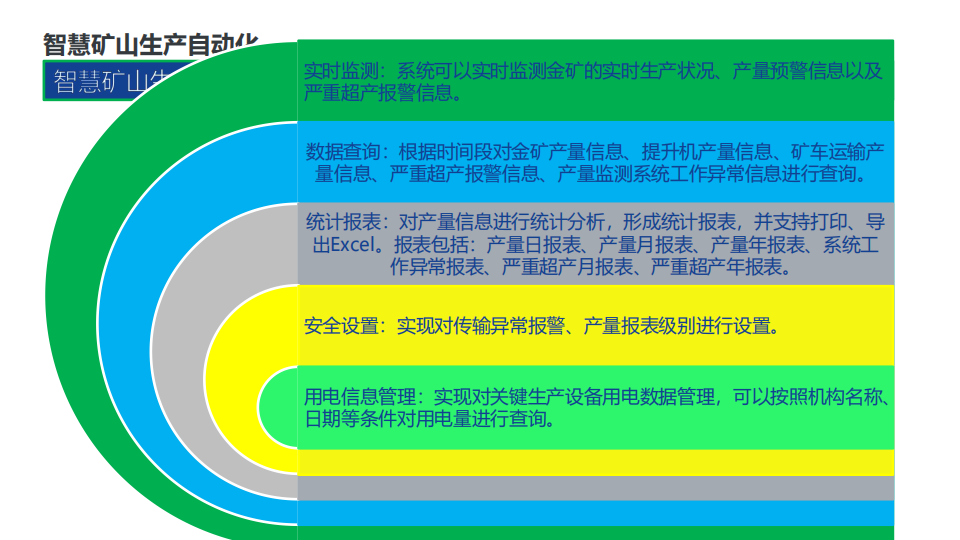

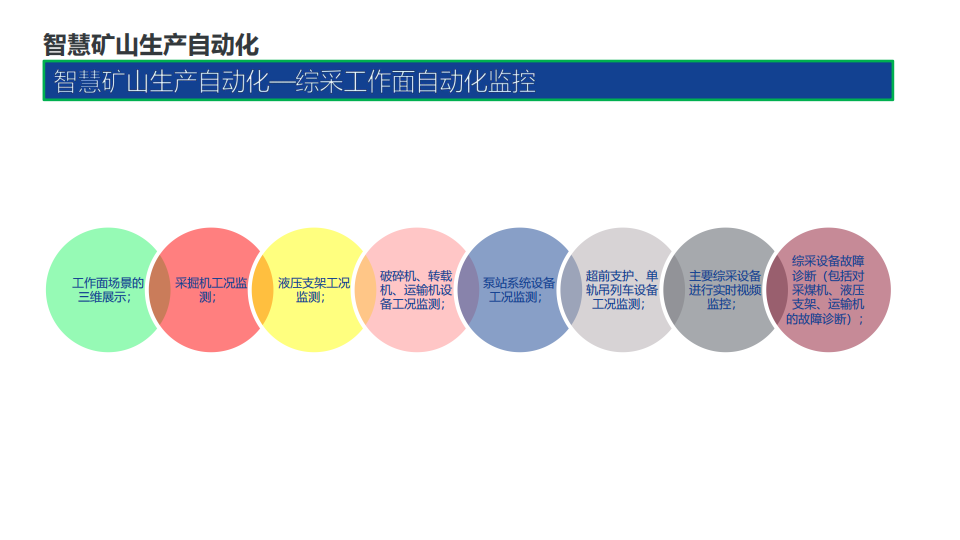

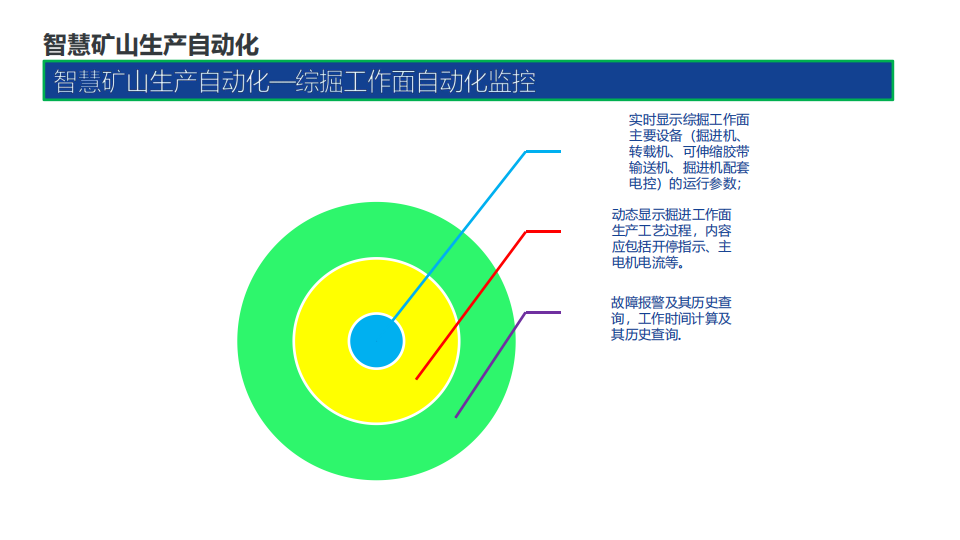

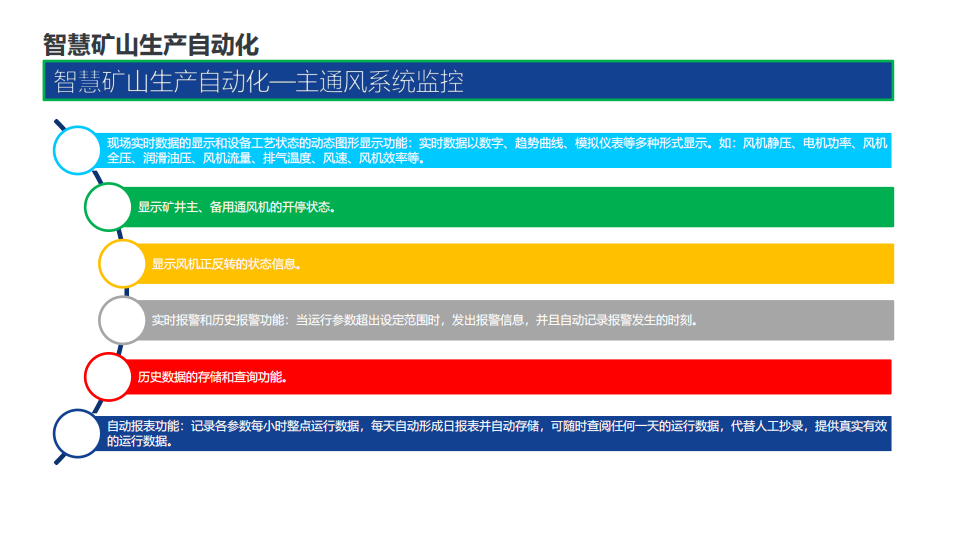

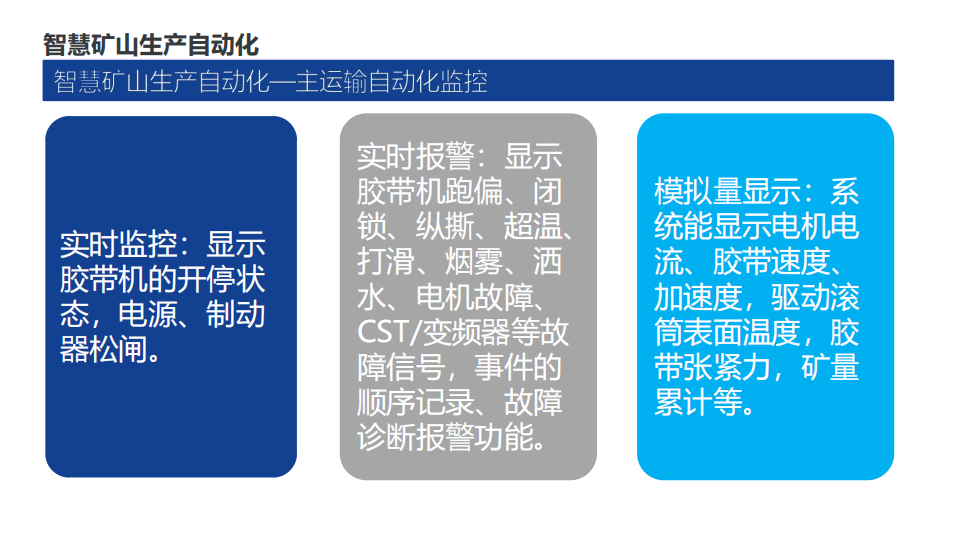

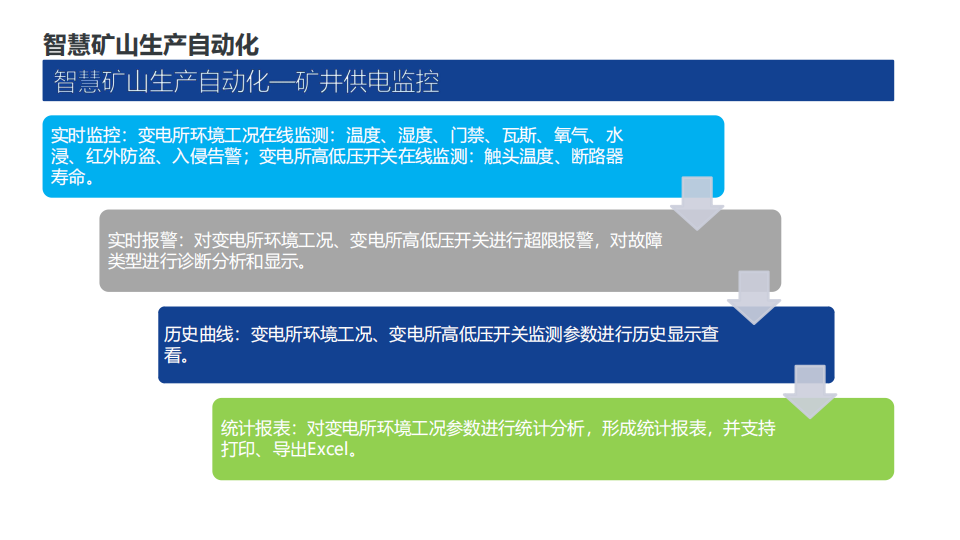

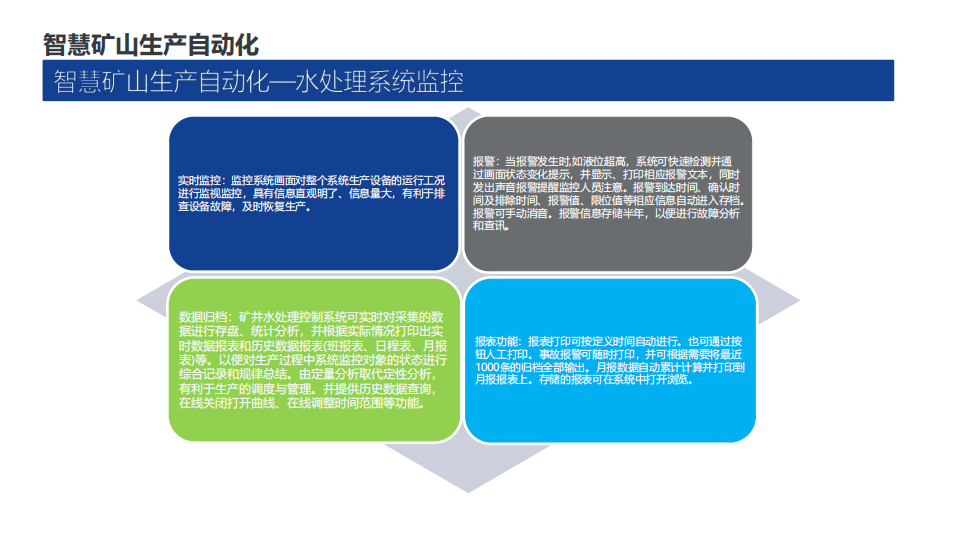

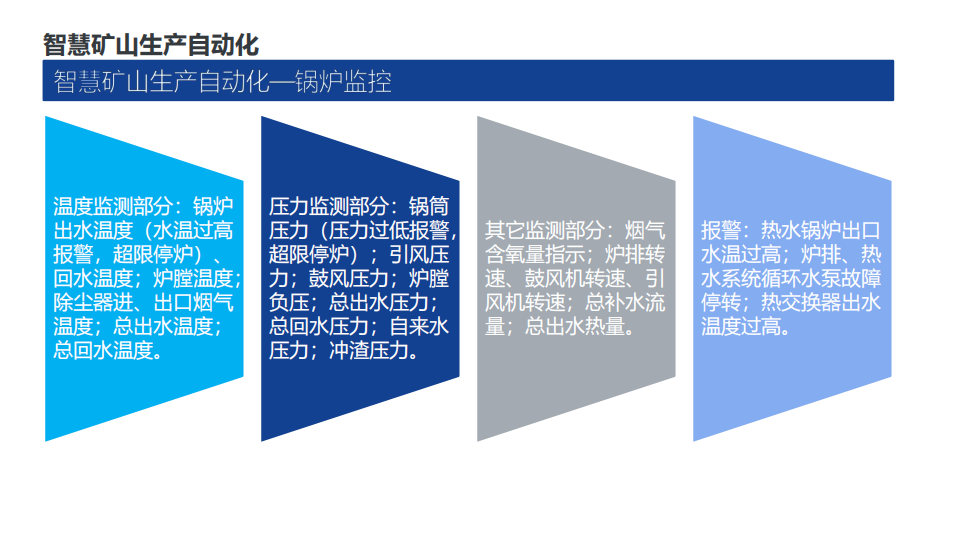

3. Core functions and technological applications • Safety production management system: The solution effectively reduces safety risks in mining operations through a dual prevention mechanism, combined with risk hazard investigation and risk grading control. The system monitors real-time data from multiple dimensions such as mining environment, personnel and vehicle location, mining pressure, fire, hydrology, etc., and provides timely warning and command through video monitoring and voice broadcasting to ensure the safety of mining operations Production automation system: Production automation covers multiple production processes such as mineral yield monitoring, automatic control of fully mechanized mining face, main ventilation system, drainage control, and power automation. Through the application of AI technology and big data, the system can monitor and analyze the operation status of production equipment in real time, and predict and warn of possible faults, greatly improving the efficiency and stability of mining production Intelligent command and dispatch: The comprehensive dispatch system in the plan is based on the deep integration of geographic information system (GIS) and building information model (BIM), providing a panoramic visualization command platform for mining production. The scheduling center can display the production status of the mine through 3D scenes, and adjust production plans and allocate resources based on real-time data, achieving intelligent scheduling and management of the production process.

4. Industry Trends and Innovation Highlights Currently, the mining industry is developing towards intelligence and unmanned direction. This solution achieves comprehensive digitization and remote management of mining operations by introducing AI technology, automated production equipment, and intelligent sensor networks. This innovative model can not only significantly reduce labor costs and safety risks, but also achieve precise resource management and scheduling in the production process, enabling mining enterprises to improve production efficiency while also responding to market changes and making flexible adjustments.