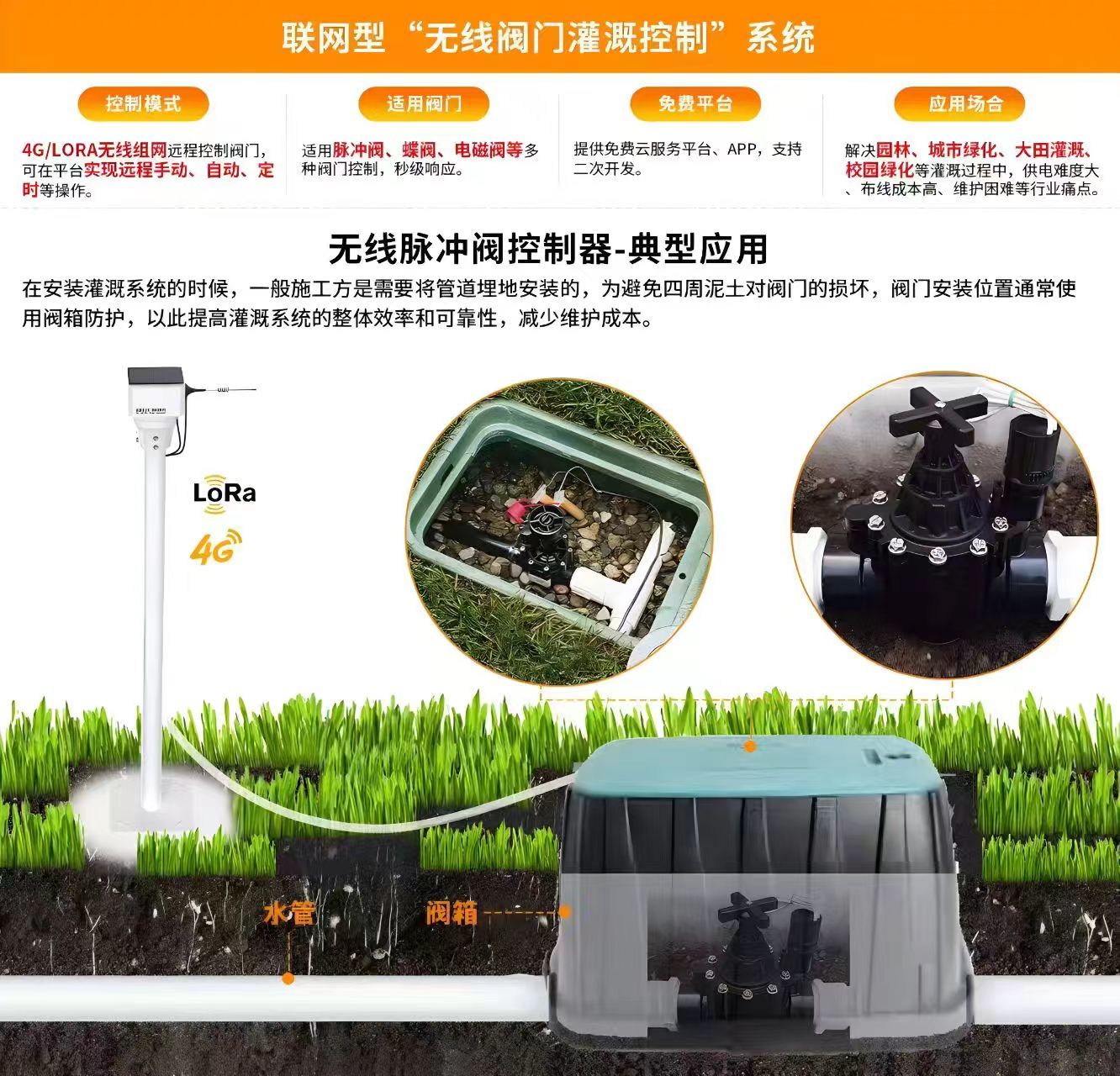

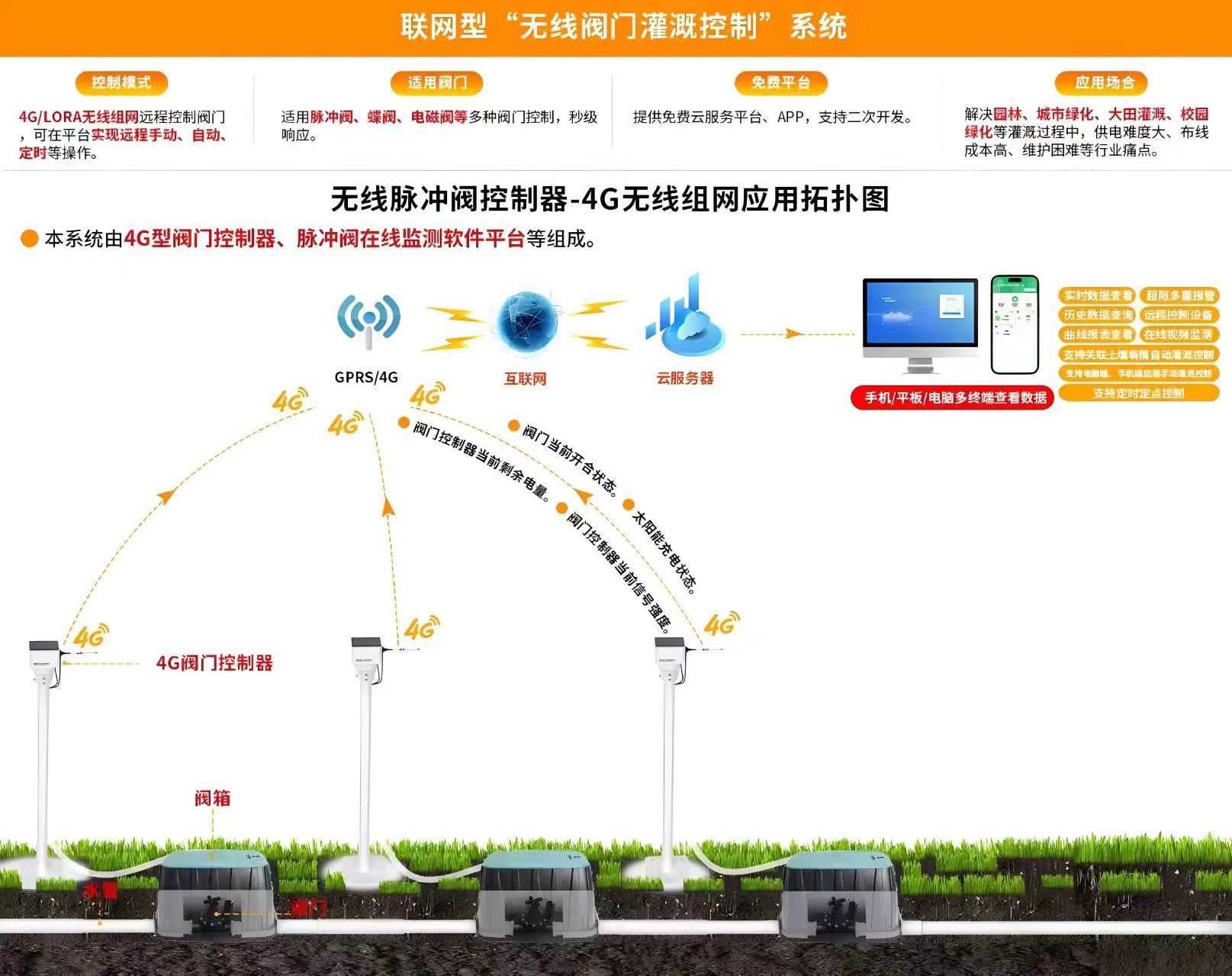

Networked "Wireless Valve Irrigation Control" System

Networked wireless valve irrigation control system:

● Wireless pulse valve irrigation controller solves the wiring pain point of irrigation industry in a wireless way!!!

● At the same time, according to the actual needs of the project, the technical idea of "multi-source fusion" can be adopted to expand the real-time monitoring of LORA type temperature and humidity sensor, LORA type soil temperature and humidity, LORA type illuminance sensor and LORA type carbon dioxide sensor, and integrate them from the equipment and platform levels to realize the overall improvement of the system type.

①, support 4G/LORA wireless network remote control valve, suitable for pulse valve, solenoid valve and other valve control, second response

②. The system supports timing irrigation control

③, support mobile phone remote manual irrigation control

④. Support automatic irrigation control related to soil moisture

● Provide free cloud service platform and APP to support secondary development

Solve the garden, urban greening, field irrigation, campus greening and other irrigation process, power supply is difficult, high wiring costs, maintenance difficulties and other industry pain points

Classification:

Key words:

Wireless valve

Irrigation system

Application recommend

Intelligent control system for brine mining and transportation in salt mines

The intelligent control system for well and mine salt mining and brine transportation is a control system that integrates automation, intelligence, and information technology, designed specifically for the well and mine salt mining industry. The system utilizes advanced sensors, controllers, and actuators to achieve real-time monitoring and intelligent control of the entire process of brine mining in mines, improving production efficiency, reducing energy consumption, and enhancing safety.

Mining intelligent power monitoring system

The mining power supply monitoring system has achieved intelligent monitoring and management of the mine power supply system through advanced technological means. The system utilizes the RS485 communication protocol to efficiently exchange data between the mining power supply monitoring substation and the switch intelligent comprehensive protection unit. The monitoring substation is responsible for collecting the power parameters of the switchgear and transmitting the data to the ground monitoring system backend through the mining network switch. This backend not only has the ability to remotely control substation equipment, but also shares data to the comprehensive automation platform of the entire mine through OPC protocol, achieving network publishing and sharing of data.

Intelligent pump room unmanned control system

Through the decision control of industrial computers, the operation status and process of equipment are automatically detected and controlled to achieve optimal working conditions, thereby effectively saving energy, reducing labor intensity, lowering operating costs, and extending equipment service life.

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!