Mining broadcasting communication system

The mining broadcasting communication system adopts TCP/IP and a new type of bus as communication protocols, mainly distributed in positions such as tunnels, waiting rooms, monkey car lines, belt lines, coal mining working faces, and excavation working faces. It can completely eliminate call blind spots, so that underground workers and rest personnel can clearly hear the sound of the speaker broadcast and alarm voice, and can communicate with the above and below the well through intercom speakers. In emergency situations, dispatchers can promptly notify underground workers to evacuate and evacuate quickly based on specific circumstances, and provide necessary information assistance for safety measures and emergency rescue. It can minimize the occurrence of safety accidents and minimize the losses caused by safety accidents to the greatest extent possible.

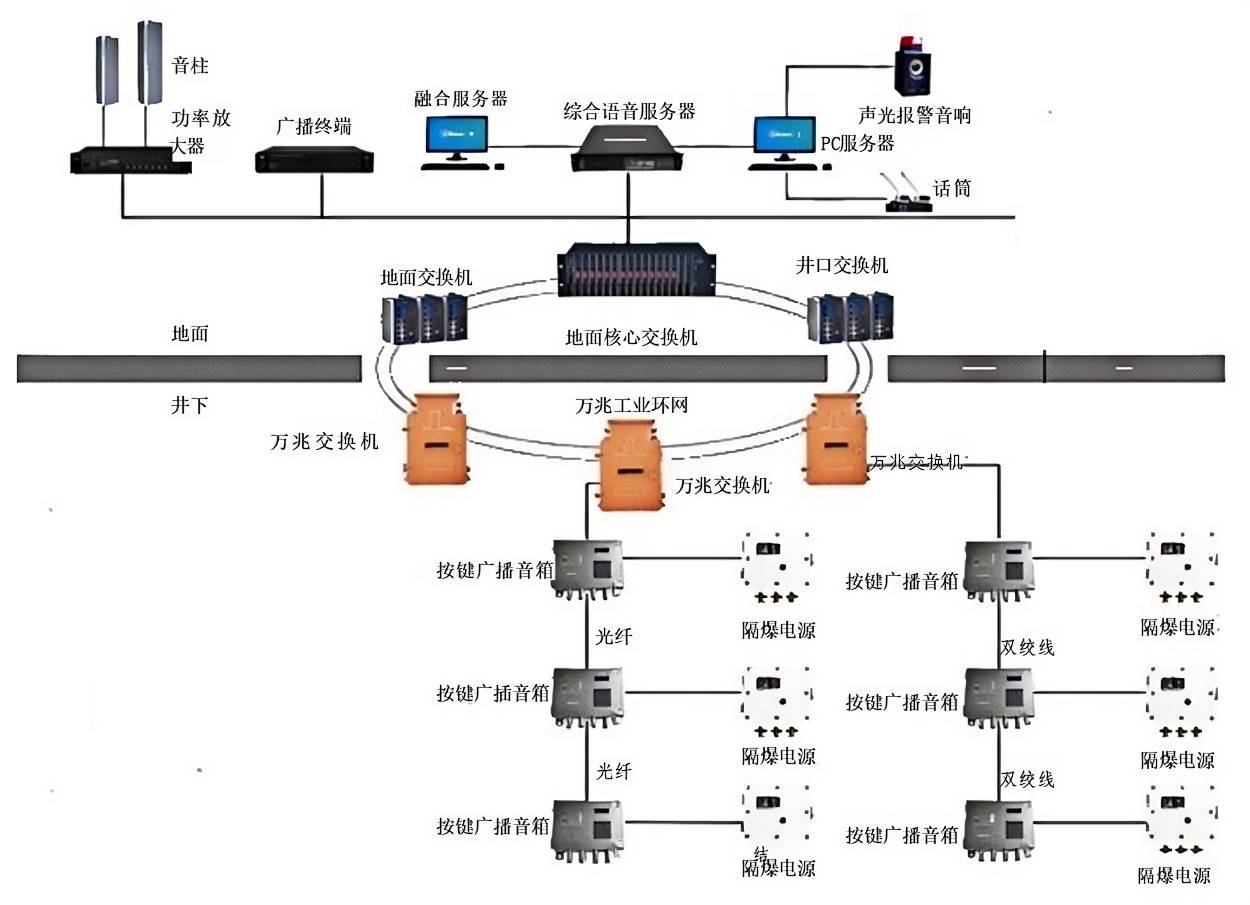

System basic structure description

Ground system:

Softswitch servers and software, clients, high fidelity microphones, and speakers based on softswitch technology;

Underground section:

Mining intrinsic safety switches, mining intrinsic safety speakers, mining explosion-proof and intrinsic safety power supplies, cables, etc.

System architecture characteristics

1. Based on Ethernet networking, deployment is simple and flexible, saving investment in line laying and easy to maintain.

2. The system can fully meet the various broadcasting functions of security alarm broadcasting.

3. The use of standard telephone mode has strong universality, making it easy to integrate scheduling systems, broadcasting telephone systems, etc. at the software level, and facilitating the development of a unified broadcasting management control interface.

4. The system is implemented using IP softswitch technology and has powerful intercom communication functions.

5. Multiple broadcasting control stations and multi-level control center modes can be set up to achieve flexible deployment of broadcasting in different zones and the entire area.

6. E1 interconnection can be achieved with the production scheduling communication system, and some scheduling telephone lines can be borrowed to achieve broadcast deployment, but it does not rely on the scheduling communication system.

7. As an independent Ethernet based secure broadcasting system, it can also serve as a backup communication system for scheduling systems in emergency situations, achieving scheduling communication.

8. Each speaker is equipped with a dial key, which can be used to call the dispatch center with one click, as well as to dial any speaker. After docking, it can also be used to make calls to wired or wireless phones.

9. Speaker with all digital dialing keys and LCD display. Call any internal or external communication terminal. Comprehensive real-time display of device status, with clear visibility of device operation;

10. Provide free broadcast software upgrades.

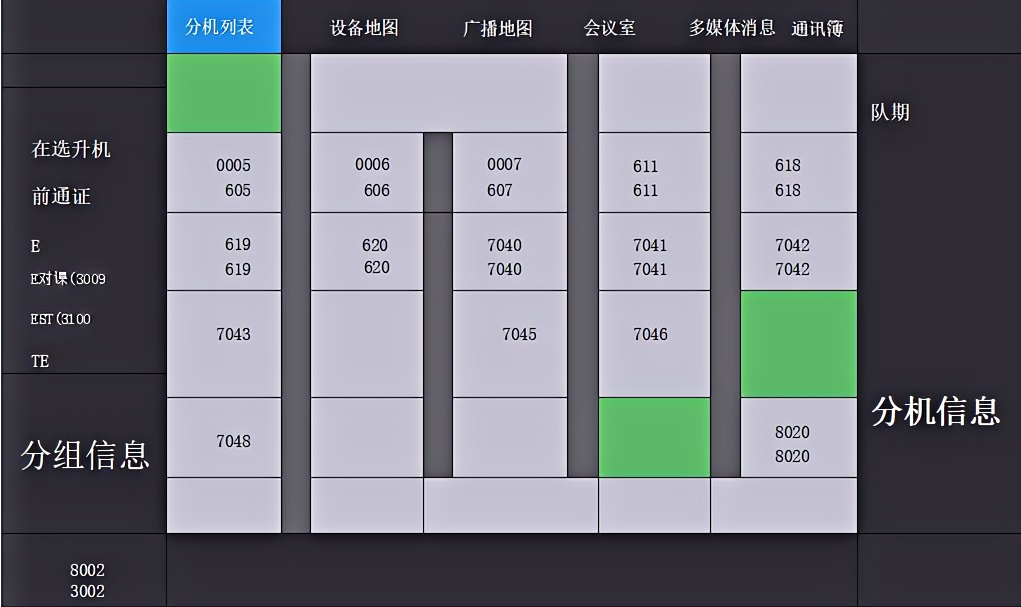

Partition broadcasting function

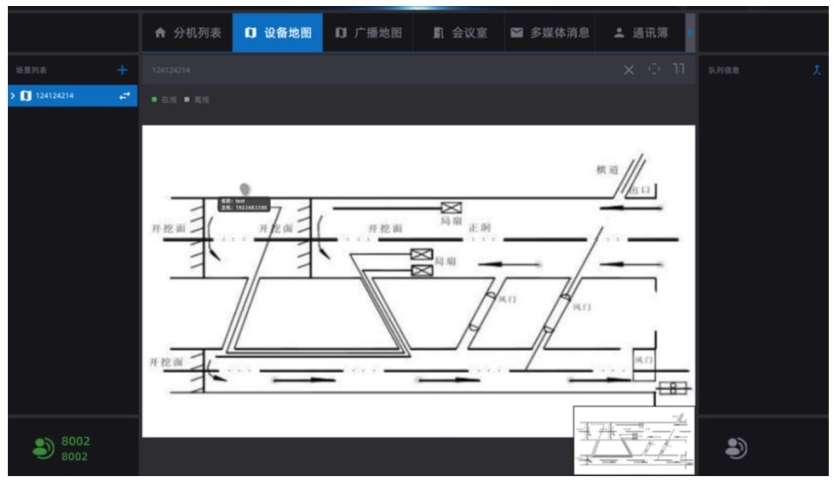

GIS map

Classification:

Key words:

Smart Mining

Broadcast communication

Application recommend

Intelligent control system for brine mining and transportation in salt mines

The intelligent control system for well and mine salt mining and brine transportation is a control system that integrates automation, intelligence, and information technology, designed specifically for the well and mine salt mining industry. The system utilizes advanced sensors, controllers, and actuators to achieve real-time monitoring and intelligent control of the entire process of brine mining in mines, improving production efficiency, reducing energy consumption, and enhancing safety.

Mining intelligent power monitoring system

The mining power supply monitoring system has achieved intelligent monitoring and management of the mine power supply system through advanced technological means. The system utilizes the RS485 communication protocol to efficiently exchange data between the mining power supply monitoring substation and the switch intelligent comprehensive protection unit. The monitoring substation is responsible for collecting the power parameters of the switchgear and transmitting the data to the ground monitoring system backend through the mining network switch. This backend not only has the ability to remotely control substation equipment, but also shares data to the comprehensive automation platform of the entire mine through OPC protocol, achieving network publishing and sharing of data.

Intelligent pump room unmanned control system

Through the decision control of industrial computers, the operation status and process of equipment are automatically detected and controlled to achieve optimal working conditions, thereby effectively saving energy, reducing labor intensity, lowering operating costs, and extending equipment service life.

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!