Research and Practice on Smart Mining System Engineering and Key Technologies

Category: Industry News

2024-10-17

1. Overview of Smart Mining System Engineering

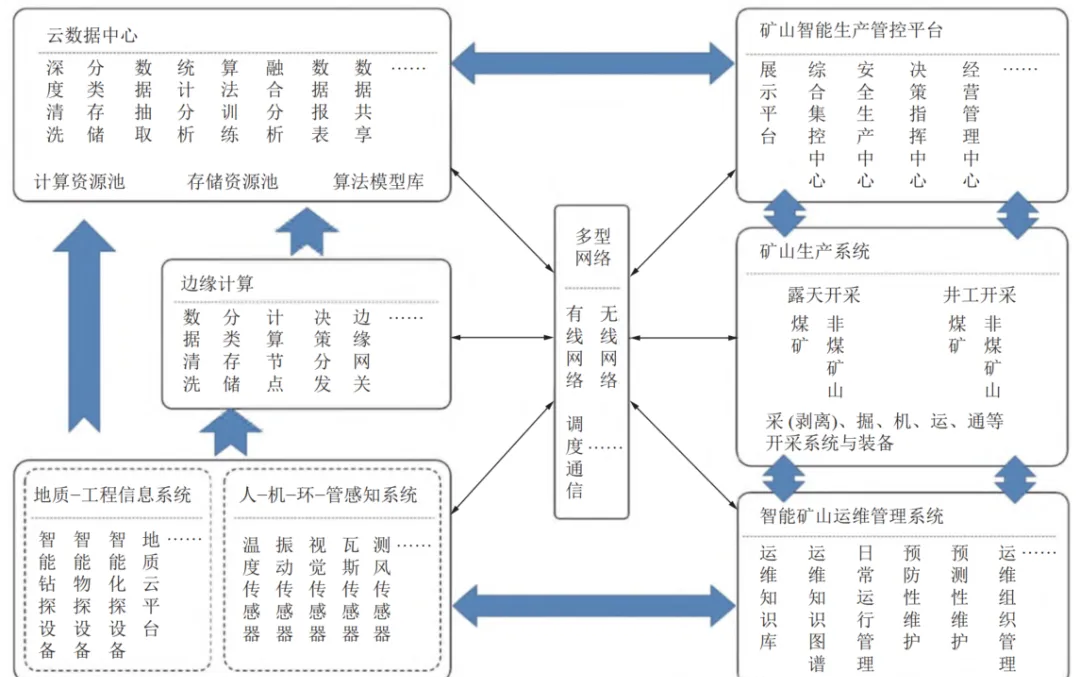

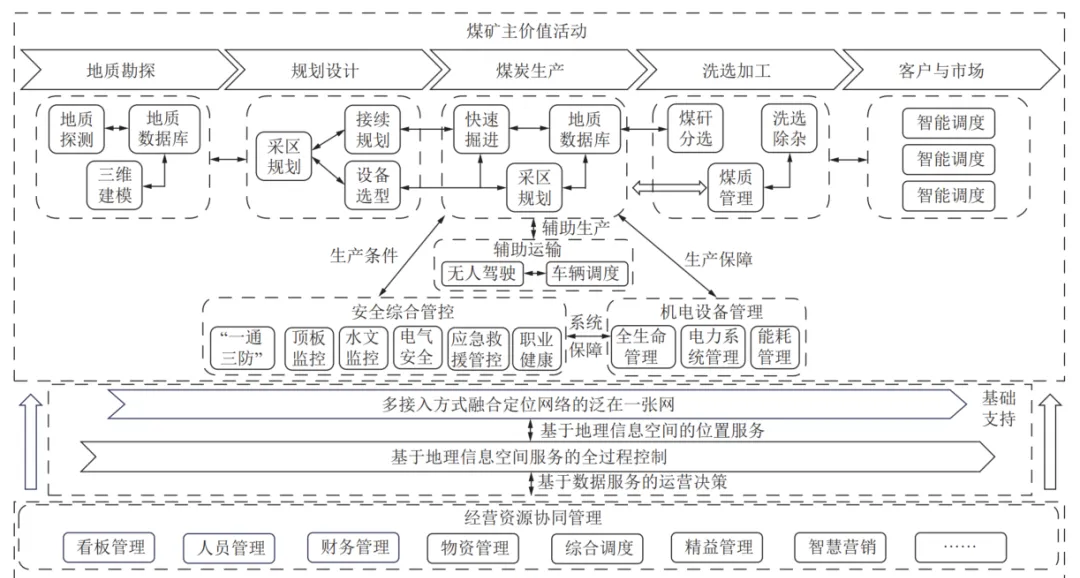

Overall technical architecture: the smart mine is divided into information perception support layer, edge computing layer, cloud data center, multi network, mine intelligent production management and control platform, mine intelligent production system, and intelligent mine operation and maintenance management system.

Existing problems: low level of intelligence in technical equipment, insufficient system integration capability, poor adaptability to complex conditions, bottlenecks in major system intelligence technology equipment, insufficient data governance capabilities, untapped 5G application scenarios, and poor reliability and adaptability of system equipment.

2. Smart mining system model and data foundation

Intelligent Mining System Engineering Model:

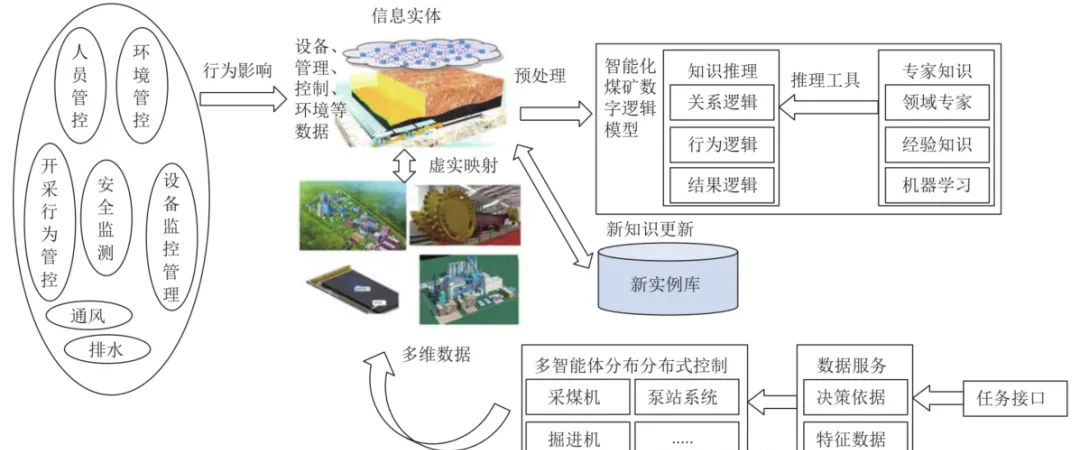

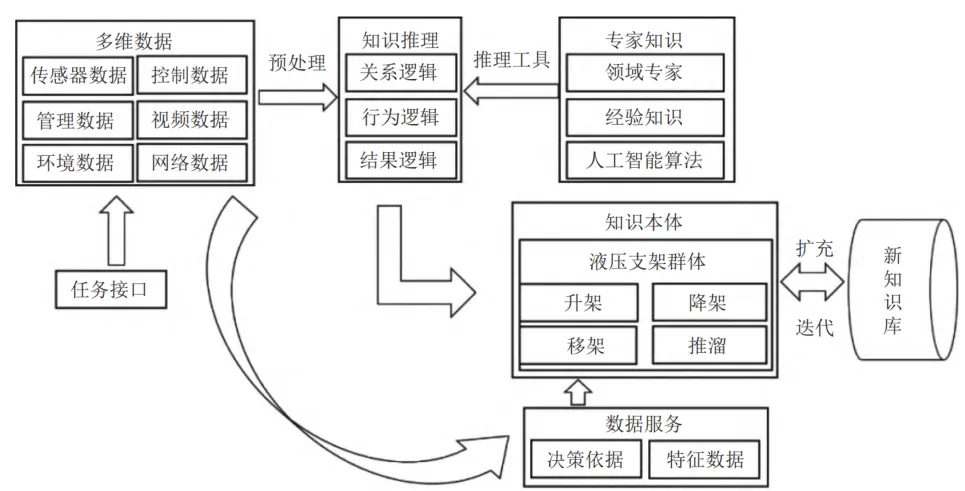

Information entity: Extract and describe physical entities with entity attributes and associated attributes. Entity attributes provide basic descriptions of information entities, including attribute information, structural information, functional information, etc; Association attributes describe the relationship attributes between information entities, including grouping/classification, hierarchical relationship attributes, importance relationship, influence relationship attributes, and behavioral attributes.

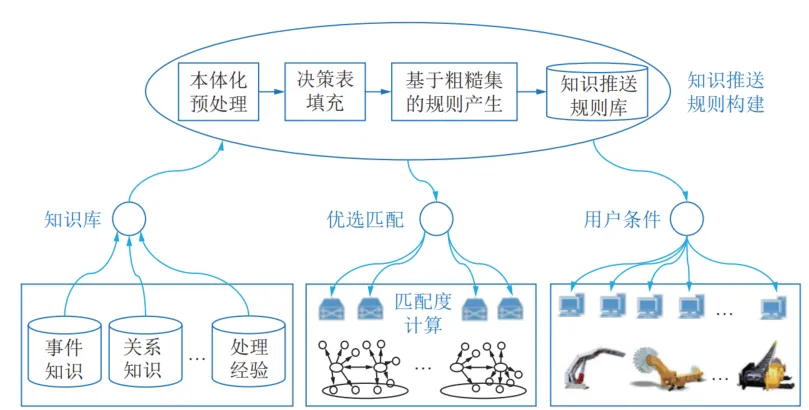

Knowledge Graph: By using Apriori algorithm to mine association rules, a smart mining domain ontology based on mining behavior is constructed, and logical relationship models between internal and external objects at various levels of smart mining are established.

Data sharing: Based on the business requirements of smart mining, tasks are decomposed to obtain ontology knowledge for control decisions, matching data is pushed to control objects, and data resources are shared and exchanged, as well as production information management.

Intelligent mine system engineering model: including communication network, big data, cloud computing, Internet of Things, industrial Internet and intelligent mine robot, providing basic support for production and operation of mining enterprises.

3. Underground space reconstruction and dynamic model updates

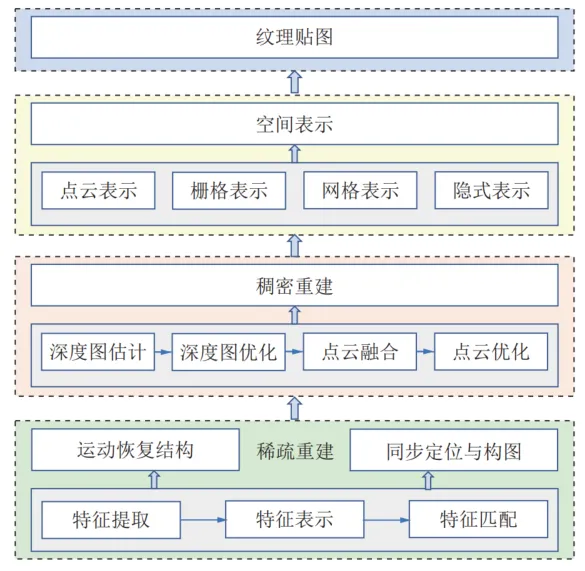

The process of underground space reconstruction includes four modules: sparse reconstruction, dense reconstruction, spatial representation, and texture mapping. Machine vision sensing data is the main component, supplemented by other sensing data, to construct a three-dimensional visual spatial model of the underground mining scene.

A framework for 3D vision and spatial reconstruction of underground mining scenes: using visible/infrared light visual data as the main source, supplemented by laser, UWB, IMU and other data, through the design of multi-sensor spatiotemporal calibration theory and noise suppression strategy, data fusion enhancement is achieved, high-quality visual images are obtained, and accurate recognition of typical targets and efficient reconstruction of spatial models of mining scenes are carried out.

4. Machine vision measurement technology for complex underground environments

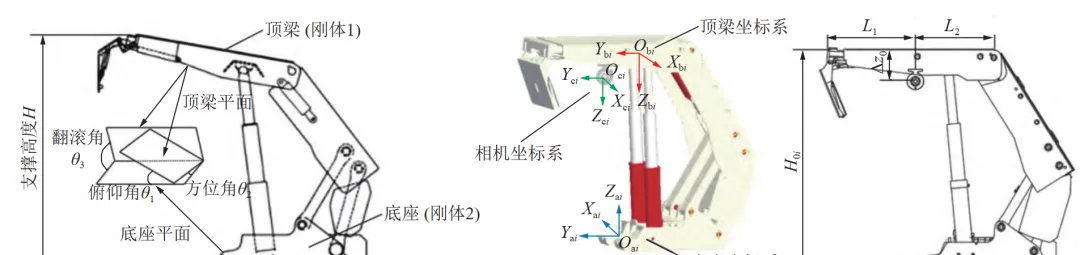

Hydraulic support single device pose detection: By installing an RGB-D camera on the top beam of the hydraulic support, the support height of the hydraulic support and the pose angle of the top beam relative to the base are measured.

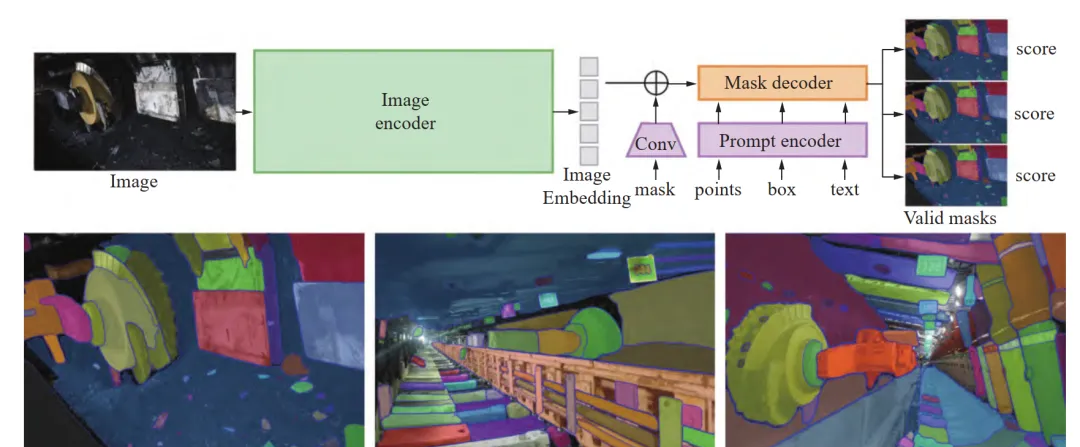

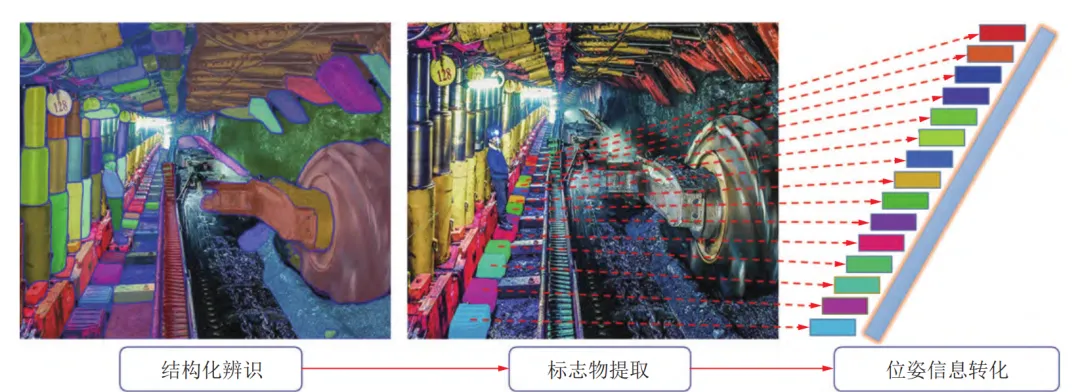

Comprehensive mining equipment (group) attitude and spatiotemporal measurement: A segmentation model based on Transformer architecture is used for structured fine-grained identification, and pose extraction is performed based on the known structural dimensions of equipment markers.

Coal rock interface recognition: The view based coal rock interface extraction process includes image noise preprocessing, image segmentation, morphological processing, contour extraction, boundary extraction, etc.

5. Risk analysis of radio frequency detonation in underground gas environment

Analysis of current standard test methods: The 6W safety limit is not applicable to the 5G frequency band, and the relevant test methods are also not applicable to 5G technology, and there is a significant safety factor in the relevant evaluation indicators.

Design of Radio Frequency Electromagnetic Energy Explosion proof Test Method: A dedicated test device for radio frequency electromagnetic energy explosion prevention was designed based on a half wave dipole antenna. The test results showed that the power limit of the 700MHz frequency band base station can be increased from the threshold power of 6W to the port power of 20W or more.

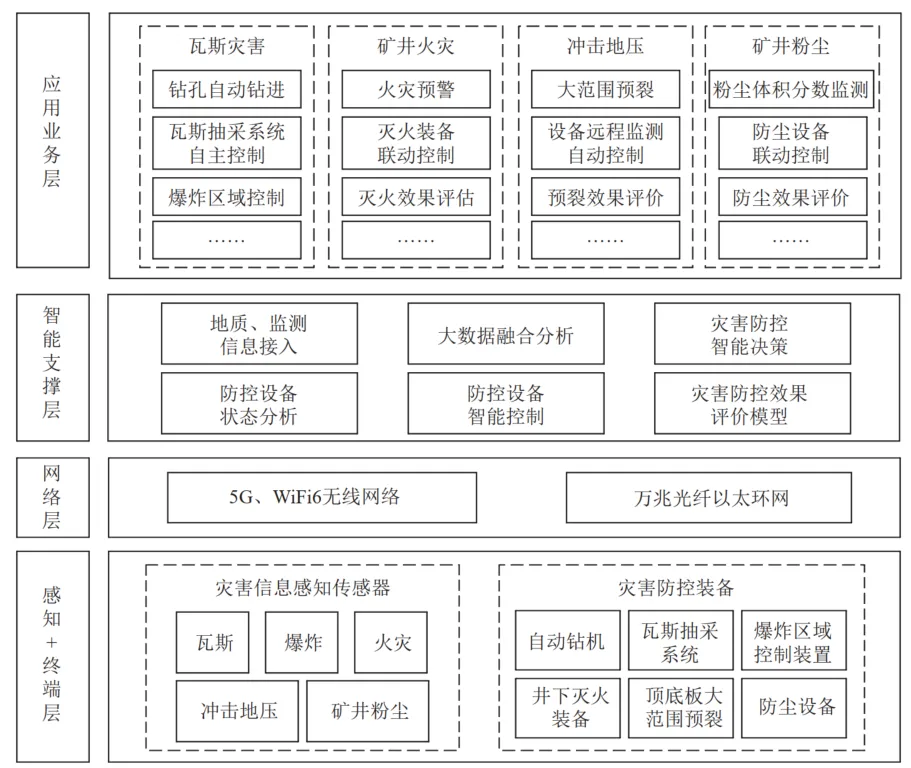

6. Full time and Space Information Perception and Closed loop Control System

The architecture of mine full time and space information perception technology: the perception control layer is responsible for information perception and execution of prevention and control instructions, the network transmission layer realizes information transmission, the intelligent support layer performs data fusion and management, and the application business layer has functions such as prevention and control scheme design.

Mine spatiotemporal information perception and fusion warning technology: including multi-source information fusion warning technology for gas disasters, comprehensive fire warning technology, mine water hazard warning system, roof and rockburst disaster warning technology, intelligent prevention and control technology for underground dust, and coal mine safety situation fusion warning technology.

7. Intelligent technology standard system for coal mines

Construction principle: Provide an overall layout and development plan, clarify standard relationships, standardize key technologies, and facilitate understanding of standard situations.

System framework: including five standard subsystems: basic universality, information foundation, empowerment platform and software, production system and technical equipment, smart park and operation and maintenance management.

Key standardization directions and fields: The basic universal standard subsystem includes basic common standards, design standards, safety common standards, intelligent common technologies, and evaluation and assessment standards; The sub system of information infrastructure standards includes mine information network, data standards, edge cloud collaboration, coal mine information security, etc; The empowerment platform and software standard subsystem include geographic information platform, big data platform, comprehensive control platform, coal industry software, artificial intelligence system, digital twin system, etc; The production system and technical equipment standard subsystem is designed for intelligent production equipment and systems in the three major production scenarios of underground, open-pit production, and coal mine washing; The subsystem of smart park and operation and maintenance management standards includes intelligent park, equipment status maintenance, operation and maintenance management, production and operation management, etc.

8. Construction Practice of Intelligent Coal Mine Giant System

Practice of Intelligent System Construction in Zhangjiamao Coal Mine:

High speed transmission network construction: covering mining industrial sites, administrative offices, and safety production, with a 5G base station coverage radius of at least 150m.

Integrated platform for coal mine safety production control: based on the intelligent control platform for coal mine safety production, coal mine big data and data management platform, and coal mine intelligent comprehensive monitoring platform.

Intelligent production and auxiliary systems: Multiple intelligent fully mechanized mining faces have been built, intelligent rapid excavation systems have been developed, and intelligent ventilation systems have been constructed.

Smart Park Construction: A comprehensive control system for smart parks has been established, which enables unified collection, storage, calculation, management, and application of information within the park.

Construction Practice of Ningtiaota Coal Mine Robot Cluster:

Target localization and recognition methods in complex application scenarios of coal mines: Developed a multi-dimensional information stitching algorithm based on multiple visual sensors and a multi-dimensional feature space global feature description method.

Standardized access technology for coal mine robots: Developed using a unified robot communication protocol and middleware based on OPC UA to ensure standardized data access and data model objectification.

Robot job scheduling strategy: Propose a similar robot coverage job scheduling strategy to ensure the shortest response time of robots in the area.

Robot cluster control and collaborative scheduling platform: divided into robot cluster layer, communication access layer, application service layer, data publishing layer, and data interaction layer.

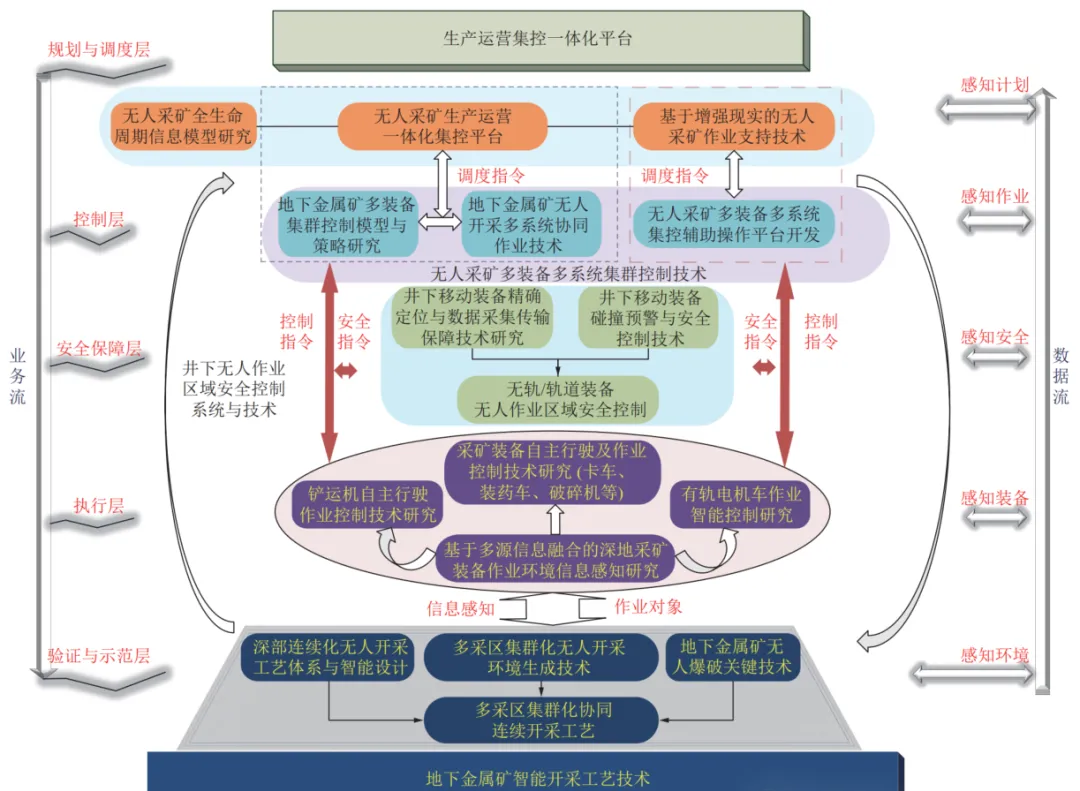

9. Practice of Intelligent Construction in Metal Mining (Well Engineering)

Intelligent Mining Technology Architecture and Key Technologies for Metal Mines: Supported by common key technologies for intelligent mining and supported by intelligent mining equipment and work systems, the overall architecture includes planning and scheduling layer, control layer, safety assurance layer, execution layer, and verification and demonstration layer. Key technologies include ubiquitous information collection technology, underground wireless communication technology, underground high-precision positioning and intelligent navigation technology, underground equipment intelligent control technology, underground metal mine multi equipment collaborative control technology, underground unmanned mining operation multi area safety control technology, and unmanned mining production and operation integrated centralized control platform.

Typical intelligent mining equipment for metal mines (well workers): including underground intelligent loaders, underground intelligent mining vehicles, underground intelligent charging vehicles, intelligent deep hole fully hydraulic rock drilling rigs, etc.

10. Conclusion and Prospect

Development Trends and Prospects: Deepen basic theoretical research, promote exploration and practice of 5G application scenarios, advance digital transformation and upgrading of mining enterprises, accelerate breakthroughs in key technologies and equipment for smart mines, focus on innovative development of the mining equipment industry, conduct research on common key technologies related to coal mine robots, promote optimization and adjustment of mining engineering majors in relevant universities, and promote the construction of smart mines towards intelligent integration and systematization.